- 03/09/2016

Foam cutter CNC series

[vc_row css=”.vc_custom_1439624677741{margin-top: 30px !important;}”][vc_column width=”1/2″][box_header title=”Technical information” bottom_border=”1″][vc_column_text]LYNX hot wire foam cutters are computer-controlled (CNC) machines, used to cut shapes in styrofoam and XPS. They are easy to operate, professional machines, with intuitive software. You will be able to start production after just one-day training.

There are several models of LYNX cutters, that differ in dimensions, and hence, with their purpose. Ones with short wire, like LYNX T1/60, are dedicated for cutting 3D letters and logos in XPS. Ones with long wire are production machines for architectural elements, foam moldings, for building and pipes insulation, packing foam and other large elements from foam. Regardless of the size all LYNX cutters provide the highest precision and quality of cut. All models are made from high class specialized aluminium profiles, equipped with precise movement mechanisms based on bearings and timing bets with steel cord. Thanks to this technological solutions we can guarantee error-free work.[/vc_column_text][/vc_column][vc_column width=”1/2″][box_header title=”How the LYNX hot wire cutters work?” bottom_border=”1″][vc_column_text]There are just a few steps to perform, to receive elements from foam.

First put a piece of foam on a machine and set starting the point. Than prepare your project in TERMCUT or import one form Adobe Ilustrator, Corel Draw, AUTO CAD or other vector graphic software. Combine objects in a single lined project just in one click. Pick a preset for your foam, and send project to the machine. Machine starts cutting.

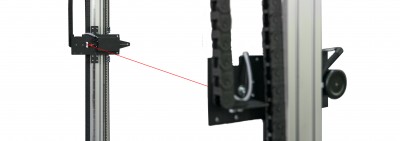

The cutting wire is constantly tensioned during the cutting process. Tensioning element cooperates with end-switch and steerage software, so device stopps if the wire is break off during the cutting process. User can easly replace cutting wire and continue cutting process.

The machine is very easy to operate. The user is not required to have any special skills. One day training is usually enough to get familiar with the device and the software!

User imagination is only the limit.[/vc_column_text][/vc_column][/vc_row][vc_row type=”full-width” top_margin=”page-margin-top” css_animation=”left-to-right” css=”.vc_custom_1640730801803{background-color: #f5f5f5 !important;}”][vc_column][announcement_box header=”ACCESORIES” header_expose=”Check all avaiable accessories list” button_label=”VIEW LIST” button_url=”/accessories” icon=”driller” button_hover_text_color=”#ed1c24″][/vc_column][/vc_row][vc_row type=”full-width” top_margin=”page-margin-top-section”][vc_column][ql_team items_per_page=”-1″ ids=”1591,1598,1599″ order_by=”menu_order” headers=”1″ headers_links=”1″ headers_border=”0″ show_subtitle=”1″ show_excerpt=”0″ show_social_icons=”0″ show_featured_image=”1″ featured_image_links=”1″][/vc_column][/vc_row][vc_row type=”full-width” top_margin=”page-margin-top”][vc_column][ql_team items_per_page=”-1″ ids=”1600,1602,1601″ order_by=”menu_order” headers=”1″ headers_links=”1″ headers_border=”0″ show_subtitle=”1″ show_excerpt=”0″ show_social_icons=”0″ show_featured_image=”1″ featured_image_links=”1″][/vc_column][/vc_row]